In today’s dynamic electronics landscape, manufacturers face a dual challenge. They must meet the demands for smaller, more powerful devices while ensuring the ruggedization and durability of components in challenging conditions. This is particularly true for printed circuit board assemblies (PCBAs) used in industrial, machining and control applications. These critical components often encounter harsh environments, including chemical exposure, dust, electromagnetic interference and physical shocks.

At RiverSide Integrated Solutions (RIS), we understand the paramount importance of ruggedization in PCBAs. Our multi-system approach allows us to tailor the degree of ruggedization to each product’s unique needs, providing a precise level of protection where it matters most.

In this article, we’ll explore the various degrees of ruggedization, from conformal coating to potting and more, that can transform standard PCBAs into resilient mechanisms ready to thrive in the toughest conditions.

Additionally, we’ll delve into advanced techniques, such as 3D printing and low-pressure molding. By the end, you’ll understand why RIS stands as a pioneer in automating PCB assembly while prioritizing ruggedness.

RUGGEDIZING PCBAS

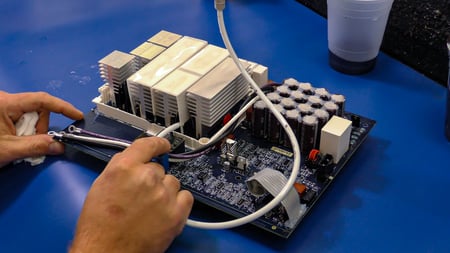

Investing in automation also allows for the economical production of PCBAs for small to medium-sized electronics manufacturers. These assemblies often go into industrial, machining and control applications. Some reasons they require ruggedization are exposure to chemicals, dust, electromagnetic interference, shock and vibration.

RIS has invested in a multi-system approach that tailors the degree of ruggedization to the product. We provide an appropriate level of protection in the vulnerable areas of the board assembly.

Among our capabilities are:

- Special Application Equipment (Robotic dispensing systems)

- Conformal coating (Silicone, Urethane)

- Potting (Epoxy, Polyurethane, and Silicone)

- Low-pressure molding technology

- 3D Printing

DEGREES OF RUGGEDIZATION

Most PCBAs can benefit from some degree of ruggedization. Imagine the intended application and all the steps the board will go through. From shipment to unboxing, assembly and connection, the opportunities are endless!

Considering all of that, it may make sense to opt for at least basic protection against moisture intrusion. A spray-on silicone conformal coating on both sides of the board usually provides this. The result is a very thin waterproof layer that fills in the gaps between the board and components. Doing this dramatically reduces the probability of moisture intrusion and corrosion.

Conformal coating is one of the most straightforward protections to apply while affording a much-improved protection against the elements.

STEP IT UP A NOTCH

STEP IT UP A NOTCHSuppose the intended operation of the PCBA includes exposure to temperature extremes, dust, dirt, chemicals, vibration or water. In that case, the design likely requires a higher level of protection.

Encapsulation or potting is the next level. Though the terms are often used interchangeably, encapsulation is not the same as potting. In general, encapsulation is less extensive and intended to protect specific areas of the board. One everyday use for encapsulation is the protection of specific components.

Especially if components are large, they are vulnerable to shock and vibration. Localized protection of these “heavy” components ensures they can withstand higher levels of shock.

RIS offers both silicone and urethane encapsulation for PCBs that we manufacture. We use a weight monitoring system to ensure the correct dispensation of the encapsulant. This ensures efficiency and accuracy.

The most common adhesives used for encapsulation are silicone or acrylic. These materials can be heat-cured or even UV-cured and are stable and inert.

THE NEXT LEVEL

Suppose we take the step up from an encapsulant to potting. In that case, this usually implies a large area up to and including the whole board. Potting generally aims to seal the electronics against extremes of exposure completely.

In an agricultural application, for example, the equipment could be used in the hot sun all day. It is also more likely to be exposed to dust and chemicals. At the end of the day, it may undergo a high-pressure washdown.

This would be a typical use case for a potted board. Marine use also commonly requires potted PCBAs due to continuous exposure to wet environments.

Potting compounds are often two-part epoxies that may undergo a heat cure.

SPECIAL CONSIDERATIONS

So far, we’ve introduced conformal coating, encapsulation and potting. All of these are done with various silicones or epoxies to add degrees of ruggedness to electronic boards.

Some PCBAs have hybrid connections (both solder and wire bond). Protecting the wire bonds in those cases is important since they can be very fragile. The most common approach to ruggedization is to use silicone as an encapsulant. This stabilizes the bonds and reduces any stresses between the chip and the bonding posts.

A unique capability we offer at RIS is using a hot-melt extruded filament under robotic control. This is a lot like a 3D printer. We utilize this precision technique to add vibration and shock resistance to specific areas of the board.

One final element worth mentioning, though it is related to ruggedness in a more peripheral way, is 3D-printed tooling. Often, board space is at a premium. The solution is to place components as close together as possible but without interference.

Along with this, the spacing has to be adequate to allow any encapsulants to flow. RIS has developed 3D fixturing that does the job. Taking time to produce custom fixtures allows tighter designs without compromising ruggedized areas.

Low-pressure molding is another protective process. At RIS we call this machine the Mold Man. As the name implies, the machine molds a plastic coating around the PCBA. This encloses the components and protects the completed assembly completely.

We fill the mold within a range of 30 to 300 PSI to ensure consistent molding.

PUTTING IT ALL TOGETHER

RIS has thoughtfully added automation, inspection and manufacturing controls to our processes, where they will have the greatest impact. This benefits the quality of the product and improves yields. We also have the experience to advise your design team when some ruggedizing will benefit your designs.

About RiverSide Integrated Solutions:

RIS is an advanced contract manufacturer providing robust solutions in circuit board assembly and product assembly. We employ more than 350 people and provide services to OEMs worldwide. We operate two state-of-the-art manufacturing facilities within the US.

With all of the choices in contract manufacturers out there, we know it can be challenging to find someone who understands your business model and has your best intentions in mind. RIS has always proven to be a win-win-focused relationship.

As your one-stop shop, we have the capabilities, capacity, quality assurance standards and resources to support all of your manufacturing needs. We understand that supply chain management is complex and very time-consuming, so we urge our customers to utilize us in the fullest capacity.

Our total-package solutions include:

- Dedicated Program Team

- Extensive supply-chain network for efficient parts procurement and kitting

- Subassembly and full box-build

- Warehousing and drop-shipping capabilities

- Reverse logistics

- Flexible order fulfillment

- Scalability to meet your needs

Contact us today at (507) 523-3220 to see how we can help with your manufacturing project, or click contact us for a quote.