In the ever-evolving landscape of manufacturing, two principles reign supreme: quality control and lean manufacturing. These principles are more than just buzzwords at RiverSide Integrated Solutions (RIS). They are deeply ingrained in our company’s DNA.

In this blog post, we’ll explore how we identify challenges, implement ingenious solutions and harness technology at RIS. We aim to not only meet but exceed manufacturing expectations.

Join us as we delve into RIS’s unwavering commitment to delivering top-tier manufacturing services.

OPTIMIZING DESIGNS FOR EFFICIENCY AND DURABILITY

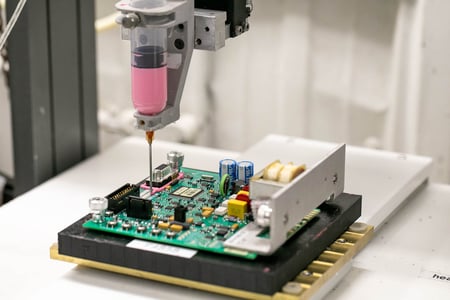

EMBRACING AUTOMATION

RIS employs a fleet of technological innovations to drive out waste and optimize processes. Efficiency, quality and cost-effectiveness are the rewards.

DATA-DRIVEN EXCELLENCE

Technology meets experience, resulting in a potent recipe for success.

THE TECHNOLOGICAL BACKBONE OF LEAN MANUFACTURING

FROM COBOTS TO 3D PRINTING: AUTOMATION IN ACTION

SMART SHELVING AND X-RAY COUNTERS: A SMART DUO

FEEDER LOW SYSTEMS AND 3D AOI: STREAMLINING OPERATIONS

We also implemented a piece of software that alerts our machine operators when a component reel is getting low. This way, the new reel can be ready and waiting when they need to make the switch.

With these efficiencies and more RIS minimizes downtime and maximizes quality.

QUALITY CONTROL THROUGH INNOVATION

Smart Solutions:

It can be programmed with the precise sequencing and torque settings required for the task. It will automatically flag any deviations from the prescribed order or torque range. This helps to eliminate defects related to missing hardware and guarantees that all components meet the required specifications.

LEAN MANUFACTURING PRINCIPLES IN ACTION

This approach not only eliminates waste associated with defects but also enhances overall process efficiency.

A LEAN CULTURE IS EVERYONE’S RESPONSIBILITY

At RIS, pursuing quality and lean excellence is a journey powered by innovation and technology. From automation to a lean culture, manufacturing excellence is our daily commitment.

Our story is a testament to the power of relentless commitment to excellence and the transformative potential of technology in modern manufacturing.

About RiverSide Integrated Solutions:

RIS is an advanced contract manufacturer providing robust solutions in circuit board assembly and product assembly. We employ more than 350 people and provide services to OEMs worldwide. We operate two state-of-the-art manufacturing facilities within the US.

With all of the choices in contract manufacturers out there, we know it can be challenging to find someone who understands your business model and has your best intentions in mind. RIS has always proven to be a win-win-focused relationship.

As your one-stop shop, we have the capabilities, capacity, quality assurance standards and resources to support all of your manufacturing needs. We understand that supply chain management is complex and very time-consuming, so we urge our customers to utilize us in the fullest capacity.

Our total-package solutions include:

- Dedicated Program Team

- Extensive supply-chain network for efficient parts procurement and kitting

- Subassembly and full box-build

- Warehousing and drop-shipping capabilities

- Reverse logistics

- Flexible order fulfillment

- Scalability to meet your needs

Contact us today at (507) 523-3220 to see how we can help with your manufacturing project, or click contact us for a quote.